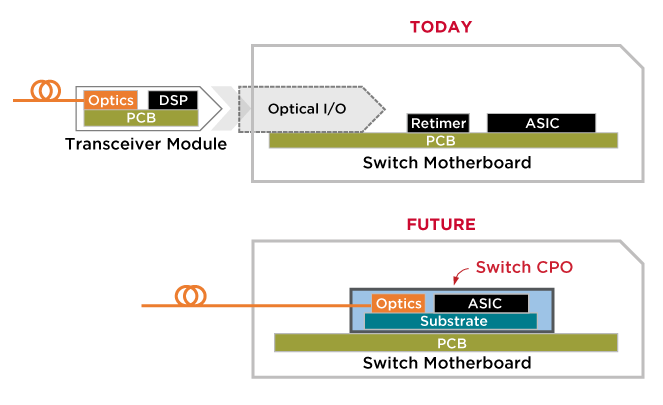

The commercialization of co-packaged optics (CPO) has been long anticipated but is becoming increasingly desirable as data needs accelerate. Co-Packaged Optics are an advanced heterogeneous integration of optics and silicon on a single packaged substrate aimed at addressing next generation bandwidth and power challenges.

As the bandwidth of data center switches increases, a disproportionate amount of power is becoming dedicated to the switch – optics interface. Reducing the physical separation between these two components by co-packaging enables system power savings which is essential to continued bandwidth scaling.

CPO brings together a wide range of expertise in fiber optics, digital signal processing (DSP), switch ASICs, and state-of-the-art packaging and test to provide disruptive system value for the data center and cloud infrastructure.

The companies and institutions working on CPO have made great strides in developing suitable electronic components. But hundreds of meters of fiber will be packed into the switch box for the first time, and faceplate connections will have unprecedented densities. As a result, the design and development of optical system solutions will also be critical elements in the success of CPO. Optical components with performance tailored to the CPO application and effective solutions for managing the fiber in the switch box are vital in optimizing the complete optical system. Three aspects of CPO deployment, in particular, hinge on the properties of the fiber and the optical interfaces: optical power loss, the trade-off between minimizing bend loss and controlling for MPI and maintaining the polarization state if external lasers are used.

Image Courtesy of Broadcom

……………………………………………………………………………………………………………………………………….

Data centers face substantial challenges as they scale, particularly in reducing power dissipation and cost per bit. CPO will play a significant role in helping to meet those challenges. In today’s data center switches, external fiber optic connections that carry data terminate on pluggable transceivers on the housing faceplate. The optical data stream is coupled to the electrical signals at that interface.

With a CPO realization of a 51.2 Tbps switch, the substrate connects a central regulator ASIC to 16 optoelectronic (O/E) tiles on the substrate perimeter. These tiles are connected to optical fiber signal cables that run to the switch box faceplate and receive power from external lasers that they modulate to produce the outgoing optical signal stream.

They communicate between the transceiver and the switch application-specific integrated circuit (ASIC) via copper traces on printed circuit boards. Under the CPO paradigm, as the optoelectronic conversion is pushed back from the faceplate to the switch substrate, long electrical traces are replaced with virtually loss-free optical fiber.

With CPO, the fiber path continues past a connector at the faceplate and into the switch box, ending at photonic integrated circuits (PICs) on optical tiles attached to the switch substrate. This shift presents the novel challenge of routing and connecting hundreds of optical fibers within a compact and crowded space, creating a need to minimize the footprint of the optics while still achieving performance and reliability targets.

CPO will soon be a reality that relies on a system of complex, interconnected components working well together. For optimum overall performance, these components must be designed with the specific requirements of CPO in mind, which for the optical subsystem include efficient and unobtrusive deployment within a crowded switch box, low power losses, absence of MPI impairments, and good reliability. Some CPO realizations also need optical polarization state control.

The familiar fiber and connectivity products, while having impressive attributes, are not optimum for the CPO application, and there is great scope for enhancing the performance of the optics by moving beyond default solutions to those specifically designed for the role.

Minimizing the optics footprint could mean routing fiber on the shortest path – consistent with the fiber properties – between the optical tile and its associated faceplate connector, but this would lead to at least eight different cable lengths for a 51.2 Tbps switch with 16 optical tiles and mirror symmetry. This proliferation of parts might be undesirable from a manufacturing point of view. If a reduced set of cable lengths were to be used, then the “constant length” routing would have to accommodate excess cable in some paths.

Image Courtesy of LightWave

……………………………………………………………………………………………………………………………………………………………………………………………………………………………………..

With space inside the switch box at a premium, the risk of mechanical interference with other components should be reduced as much as possible. When building switch boxes containing hundreds of fibers, it will be essential to have them deployed predictably while minimizing trouble spots like crossings and avoiding issues such as cable buckling.

This management goal will be greatly facilitated by using tightly bent fiber to follow short paths between the faceplate and chip. With typical telecommunications-grade single-mode fiber, too much light may be lost at these bends, but we can mitigate this by using bend-insensitive fiber designs. However, in using such designs, care will be required to control multipath interference (MPI).

Power can be coupled and propagated in more than one fiber mode at each optical interface in the switch box (e.g., connectors, FAUs). Given the short fiber lengths likely to be used in CPO, power in higher-order modes (HOMs) will not be extinguished before the following interface, where the multiple modes will interfere with each other – the phenomenon known as MPI – ultimately causing wavelength-dependent power at the detector. At some wavelengths, that power reduction could be up to twice in decibels, arising from the independent losses at each interface.

Thus, unmitigated MPI could complicate some benefits of using fiber with low bend-loss. For these systems, a bend-insensitive fiber that also suppresses MPI in very short fiber lengths would need to be designed. One potential approach is to reduce the fiber cut-off wavelength to increase HOM loss substantially.

Even if MPI is reduced to insignificance, the coupling losses at those interfaces matter, too. The redesigned bend-insensitive fiber must maintain low coupling loss to Corning® SMF-28® Ultra or other fiber used in the data center to connect switches. This imposes constraints on the mode-field diameter of the CPO signal fiber.

To permit practical, low-cost provisioning of the switch box optical cables, the fiber management approach must include some means to accommodate length variations introduced by the cable manufacturing process. One strategy is to tie down the cable at points along its path and allow it to take a relatively unconstrained path between these tie-down points. The smaller the radius of curvature of that path, the less a bundle of cables will spread out for a given length variation.

An alternative is to provide specific accumulator structures to contain excess cable length. To keep such structures unobtrusive, the fiber should tolerate deployment in very tight loops, as small as 10-mm in diameter, retaining its low-bend loss and high reliability. These attributes are required of fiber that lends itself to “shortest path” and “constant length” routing.

Conclusions:

CPO will soon be a reality that relies on a system of complex, interconnected components working well together. For optimum overall performance, these components must be designed with the specific requirements of CPO in mind, which for the optical subsystem include efficient and unobtrusive deployment within a crowded switch box, low power losses, absence of MPI impairments, and good reliability. Some CPO realizations also need optical polarization state control.

The familiar fiber and connectivity products, while having impressive attributes, are not optimum for the CPO application, and there is great scope for enhancing the performance of the optics by moving beyond default solutions to those specifically designed for the role.

References:

https://www.broadcom.com/info/optics/cpo

https://www.lightwaveonline.com/data-center/article/14300451/datacenter-providers-see-future-proofed-possibilities-in-co-packaged-optics